PET stands for polyethylene terephthalate, which is a type of plastic material used to make a wide variety of products, including bottles, containers, and packaging. A preform, on the other hand, is a specific form of PET used in the manufacturing of plastic bottles.

A

Preform PET mould is a small, tubular-shaped piece of PET resin that is formed through a molding process. It is typically made to the shape and size of the final bottle, but without the neck and cap. The preform is then heated and stretched in a blow molding machine, which forms it into the final bottle shape.

In other words, a PET preform is a stage in the manufacturing process of a PET bottle. It is the initial form of the bottle before it is blown into its final shape.

PET (Polyethylene terephthalate) molds are used for manufacturing PET products through the injection molding process. Here are the steps to perform PET mold:

1.Design the mold: The first step is to design the mold according to the requirements of the product. The mold design should consider the size, shape, and features of the product.

2.Material selection: Choose a suitable material for the mold. Steel is the most common material used for making PET molds due to its durability and high heat resistance.

3.Mold making: The mold-making process involves cutting, drilling, and milling the steel material to form the mold cavity.

4.Heating and injection: The PET material is heated to a molten state and injected into the mold cavity under high pressure.

5.Cooling: The mold is then cooled to solidify the PET material and take the shape of the mold cavity.

6.Ejection: Once the PET material is cooled and solidified, the mold is opened, and the product is ejected from the mold.

7.Finishing: Finally, any excess material is trimmed, and the product is finished according to the requirements.

Performing PET mold requires expertise and specialized equipment. It is essential to follow proper safety measures while working with hot materials and high-pressure equipment.

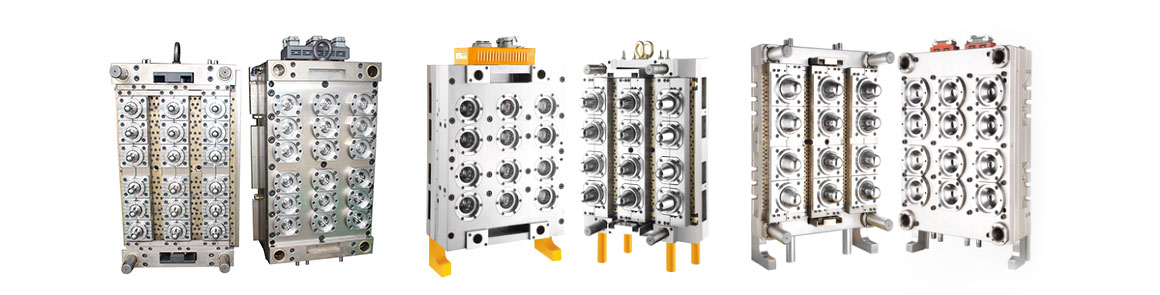

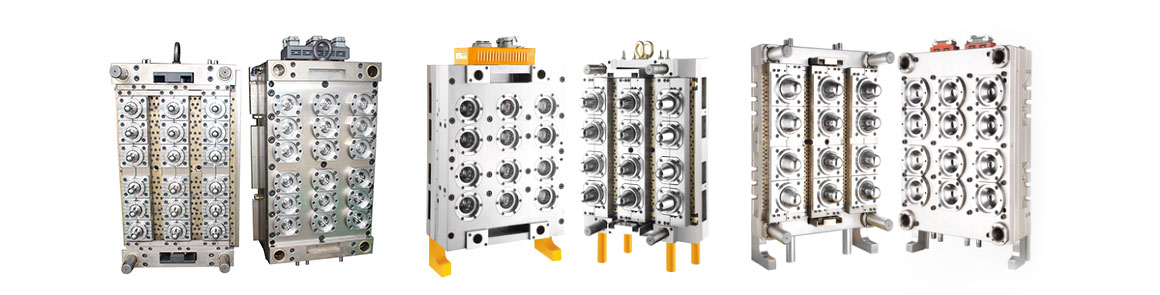

Wide mouth preform mould

Eternal life pursues the highest mold performance. Produce high quality preforms and use corrosion resistant steel to optimize preform production. Yongsheng mold has a long life. The mold design guarantees quick and easy maintenance. Yongsheng molds are easy to use, and regular maintenance work can be done directly on the machine in the shortest possible time. Mold parts are easy to replace and can produce different preforms on the same mold. Hard mold parts guarantee mold life and minimize maintenance. We can product 80-300mm,4-32 cavity self-lock width preform mould.At present, there are three series of PET preform molds, including double lock pneumatic needle valve tube blank mold. Double lock adjustable eccentric pneumatic needle valve preform mold, ordinary no-gate preform mold. The company uses advanced CAD for mold-assisted design. The shape of the preform is optimized for the final plastic bottle to ensure the final plastic molding quality. The double-lock pneumatic needle valve tube blank mold and the double-lock adjustable eccentric pneumatic needle valve preform mold adopt multi-dimensional cone positioning system to ensure the plastic thickness of the plastic bottle is consistent. At the same time, the unique hot runner system of Yongsheng Mould ensures the same pressure and PET flow ratio of each cavity.